I hold a Bachelor’s degree in Mechanical Engineering and a Master’s degree in Physics from Birla Institute of Technology and Science, Pilani. My academic journey took an interdisciplinary turn during my undergraduate studies, igniting a passion for Renewable Energy. This led me to pursue a specialized Master’s program in Renewable Energy (RENE), spanning two prestigious institutions: KTH Royal Institute of Technology in Stockholm for the first year and Ecole Polytechnique in Palaiseau for the second year. For my master’s thesis, I conducted research at IPESE, and currently, I am engaged in doctoral studies at IPESE and Ecole Polytechnique Federale de Lausanne, in collaboration with CIRAIG.

My research

Since the Industrial Revolution, global ocean temperatures have increased by nearly 1 °C, contributing significantly to sea-level rise and broader climate change impacts. This warming is primarily driven by anthropogenic greenhouse gas emissions. Industrial activities alone account for approximately 30% of global emissions, amounting to nearly 54 gigatons of CO₂-equivalent annually. To limit global temperature rise to 1.5 °C, the remaining carbon budget is estimated at around 250 gigatons of CO₂-equivalent, underscoring the urgency of rapid and large-scale industrial decarbonization.

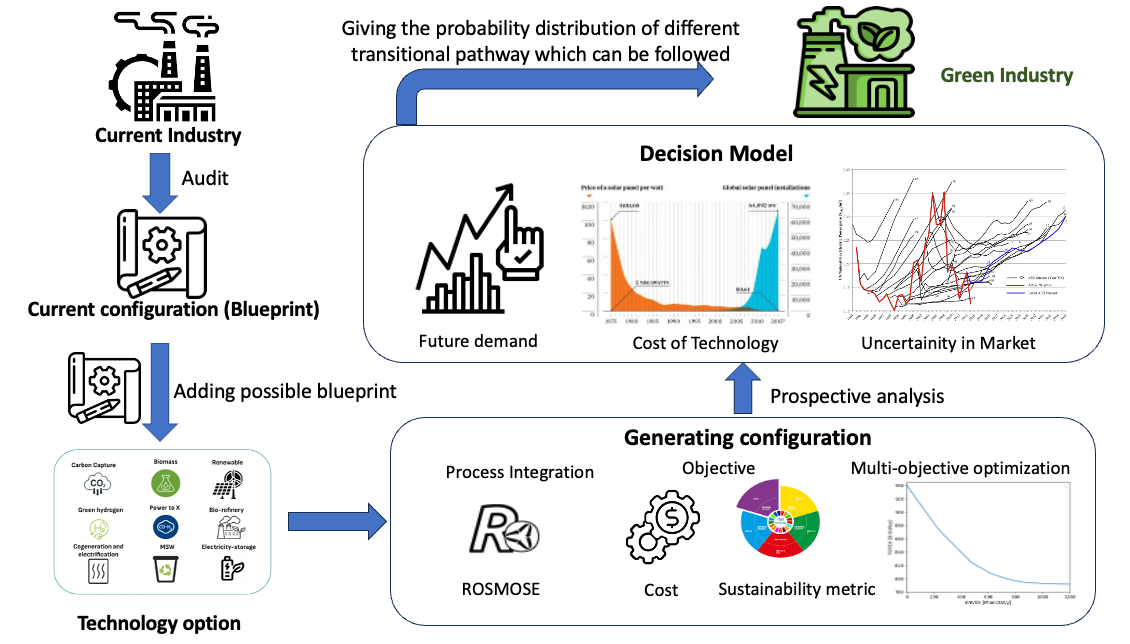

This research directly addresses the critical need for industry-wide alignment with societal net-zero trajectories. Operating within dynamic market environments shaped by the rapid deployment of renewable technologies and evolving policy frameworks, the study aims to chart feasible and robust pathways for sustainable industrial transformation.

Industrial systems can be conceptually divided into foreground and background processes based on the degree of control exercised by firms. Foreground processes comprise activities over which industries have direct operational control, while background processes include upstream and downstream activities—such as energy supply and material production—where direct control is limited or absent. While significant progress has been made in introducing operational flexibility and dynamic modeling in foreground systems, background processes are typically represented using Life Cycle Assessment (LCA) databases, such as ecoinvent. However, this approach presents two major limitations. First, many databases lack strict mass and energy balance consistency, raising concerns about thermodynamic validity and the reliability of derived results. Second, these databases are largely static and rely on unidirectional links, failing to capture feedbacks between industrial demand, technological change, and background system evolution.

To overcome these limitations, this project introduces dynamic background modeling through the development of blueprints (both process and technologies) that are thermodynamically consistent and adaptable over time. These blueprints establish bidirectional linkages between foreground and background systems across multiple industrial sectors. In cases where detailed background models are unavailable, the study leverages enhanced LCA databases that are energy-balanced and updated to reflect prospective environmental impacts.

Development of blueprint

In the a thorough audit of current industry infrastructure and operations. It then develops comprehensive blueprints for decarbonization, considering a range of available technologies and future industry needs. Using advanced techniques like Process Integration through Mixed Integer Linear Programming, the research generates and optimizes various blueprints at the company level. By integrating lifecycle metrics, the focus is on identifying energy-efficient configurations and identify appropriate symbiosis within and outside the industry.

Graphical abstract