Techno-economic and environmental assessment of sustainable thermochemical pathways for olefins production promoting carbon circularity

Authors: Oktay Boztas, Meire Ribeiro Domingos, Daniel Florez Orrego, François Marechal

Available at: https://doi.org/10.1016/j.renene.2025.124303

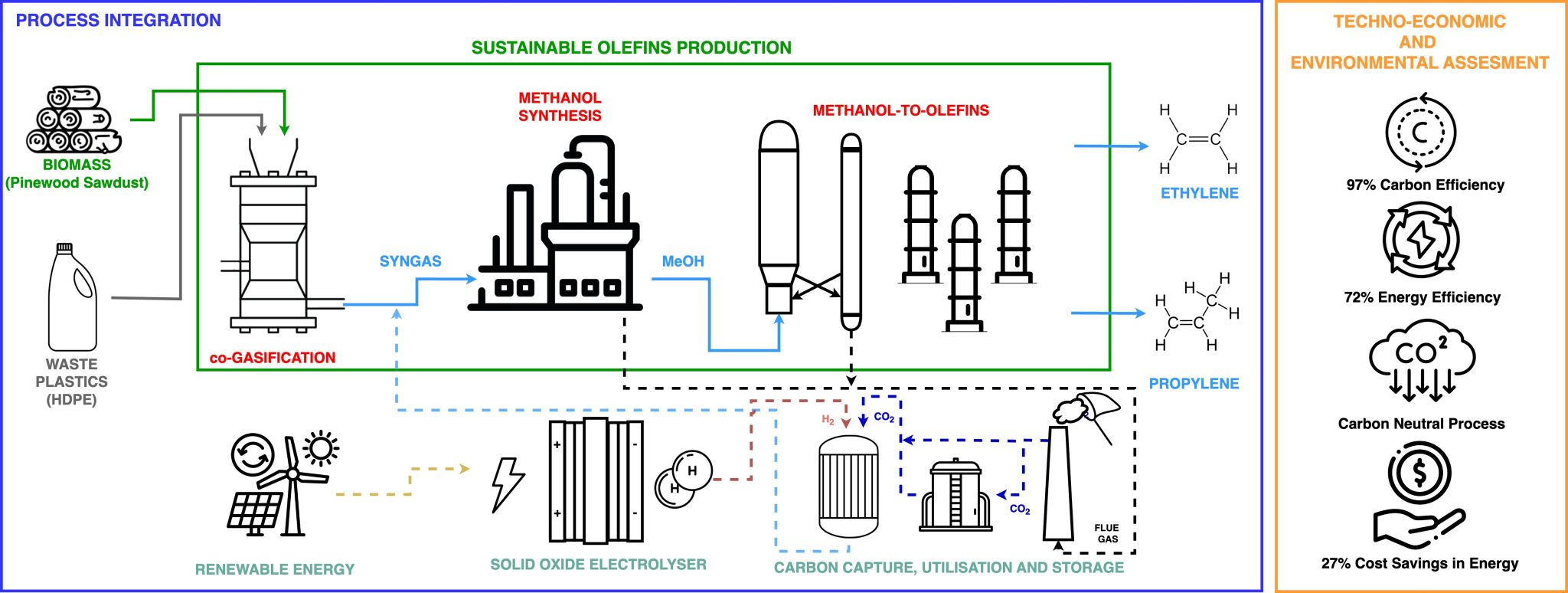

The Industrial Process and Energy Systems Engineering group at EPFL has carried out a comprehensive techno-economic and environmental assessment of alternative routes for producing light olefins from waste plastics and biomass. Olefins such as ethylene and propylene are essential intermediates in the chemical industry, yet their conventional production via steam naphtha cracking (SNC) is highly energy-intensive and responsible for nearly 400 Mt of CO₂ emissions annually, corresponding to about 30% of the chemical sector’s total footprint.

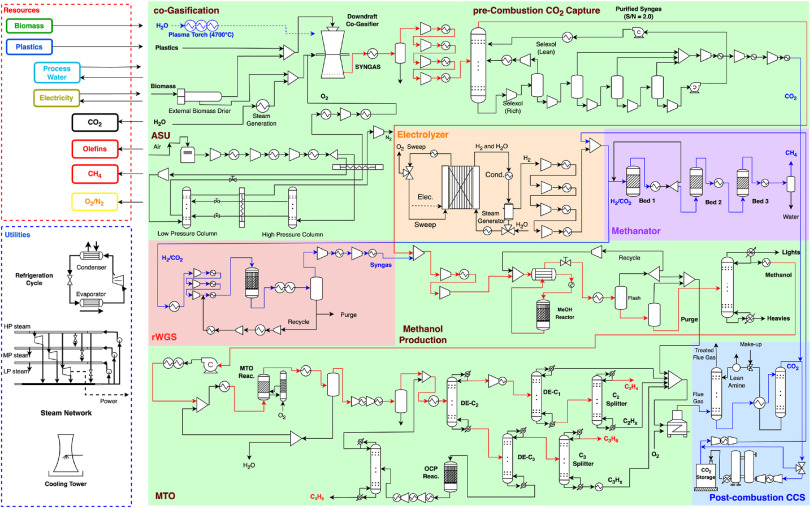

This study evaluates eight process configurations that integrate:

- Autothermal or plasma gasification of mixed plastic and biomass feedstock,

- Methanol synthesis and methanol-to-olefins (MTO) conversion, and

- Carbon capture, utilization, and storage (CCUS) technologies, including geological injection, methanation, reverse water–gas shift (rWGS), and solid oxide electrolysis cells (SOEC/co-SOEC) for CO₂ upgrading.

🌱 Environmental performance

- Carbon efficiency is substantially enhanced, reaching up to 97% in methanation and rWGS pathways, compared to ~55% for steam naphtha cracking (SNC).

- All alternative configurations eliminate direct fossil CO₂ emissions, since fossil carbon in plastics is incorporated into products rather than released.

- Net-negative emissions are achieved in plasma gasifier configurations coupled with methanation or rWGS, as biogenic carbon from biomass is embedded in hydrocarbon products rather than emitted.

- Process energy efficiency increases from ~56% SNC to ~72% in the best-performing configurations, supported by extensive heat recovery and steam network integration.

⚙️ System operation and flexibility

- Electricity-intensive units, particularly SOEC systems, are scheduled according to seasonal electricity price dynamics. By temporarily storing CO₂ in winter (high-price periods) and upgrading it in summer when renewable electricity is abundant, total electricity costs can be reduced by ~27% annually.

- Seasonal CO₂ storage requirements reach up to 31 kt CO₂ (≈27,000 m³ in liquid form) in the most power-demanding setups, enabling flexible operation without compromising carbon performance.

- Plasma gasification is more electricity-intensive (≈1.9 MWh per ton of dry syngas), but generates syngas with lower CO₂ content, thereby improving downstream conversion yields.

💰 Economic assessment

- Under current market conditions, autothermal gasification with pre-combustion CO₂ capture and injection is the only configuration achieving a positive net plant profit, although it exhibits lower carbon performance.

- Configurations integrating CO₂ upgrading (rWGS + SOEC or co-SOEC) are not yet profitable due to high electricity consumption and capital expenditures of electrolysis. However, they deliver marked improvements in carbon efficiency and net emissions, in some cases reaching near-neutrality or net-negative values.

- When emissions and economics are evaluated simultaneously, these CO₂-upgrading pathways belong to the Pareto-optimal set: they are not the most cost-effective today, but they represent robust trade-off options that become attractive as the cost of renewable electricity declines and electrolysis technologies mature.

💡 Implications

The study highlights that integrating thermochemical recycling, advanced CO₂ utilization, and renewable integration can transform plastic and biomass waste into valuable olefins while decoupling production from fossil resources. Beyond direct emissions reduction, these pathways embed circular carbon principles, progressively reducing reliance on virgin feedstocks and enabling the development of next-generation sustainable plastics aligned with climate neutrality targets.

🔗 Read the full paper: https://lnkd.in/e_Kd7rq6