EPFL researchers are awarded the AIDIC Best Poster Award at the ESCAPE 34 - PSE 24 International Conference in Florence, Italy

Researchers from the Industrial Processes and Energy Systems Engineering group at EPFL have been awarded the AIDIC Best Poster Award at the 34rd European Symposium on Computer Aided Process Engineering – ESCAPE 34 and International Symposium on Process Systems Engineering – PSE 24, held from June 2nd to 6th, 2024, in Florence, Italy.

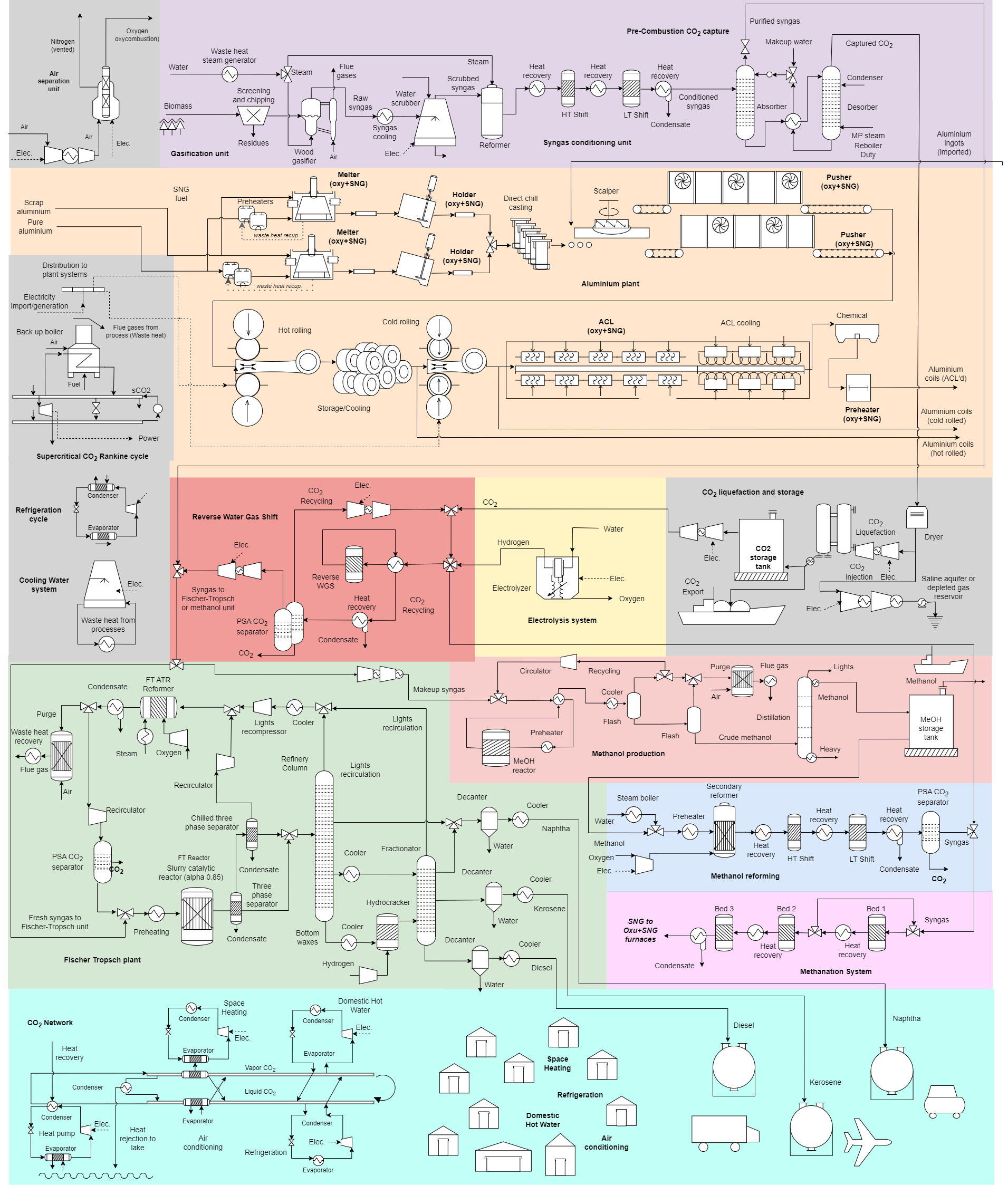

The poster entitled “Renewable energy integration and waste heat valorization in aluminum remelting mills for the co-production of kerosene and methanol” was recognized for its outstanding contribution from the perspectives of sustainability and innovation.

The work co-authored by Daniel Flórez-Orrego, Dareen Dardor, Meire Ellen Gorete Ribeiro Domingos, Reginald Germanier and Francois Marechal, has been supported by the Swiss Federal Office of Energy SFOE in the framework of the EnergieSchweiz funded projects for industrial decarbonization.

In total, five works have been presented during the ESCAPE 34 - PSE 24 co-authored by Dr. Daniel Florez-Orrego and colleagues and they are listed below:

Florez-Orrego D., Dardor D., Ribeiro Domingos M., Germanier R., Maréchal F. Renewable energy integration and waste heat valorization in aluminum remelting mills for the co-production of kerosene and methanol

Salman Muhammad, Florez-Orrego Daniel, Correa-Laguna Juan, Maréchal François, Léonard Grégoire, Systematic Analysis of Energy Transition Pathways for Emission Reduction in the Flat Glass Industry Using MILP Formulation,

Dardor Dareen, Florez-Orrego Daniel, Ribeiro Domingos Meire, Germanier Reginald, Margni Manuele, Maréchal François Co2 Capture and Management Strategies for Decarbonizing Secondary Aluminium Production,

Ribeiro Domingos Meire, Florez-Orrego Daniel, Dardor Dareen, Maréchal François, Enhanced Sustainable Natural Gas Production Using Biomass Biodigestion and Gasification Integrated with Solid Oxide Electrolysis Cell,

Ravi Sai Sudharshan, Orrego Daniel Alexander Florez, Sharma Shivom, Maréchal François, A Comparative Study of Orc Working Fluids Performance in Ultra Low-Grade Waste Heat Recovery from Data Centres.

Abstract

The aluminium sector relies on natural gas for the conversion of recycled scrap into new feedstock, which results in substantial atmospheric emissions. Hydric resources are also impacted, as they serve as heat sinks for the waste heat generated during the casting process. Other chemical industries are also responsible for a large production of waste heat, offgas and environmental emissions, which hinders efforts to decarbonize the sector that depend on them. Methanol and transportation fuels production are examples of those industries. Accordingly, there is a significant potential to decarbonize these productive activities via enhanced waste heat recovery and integration of renewable energy sources. The energy integration of aluminium, methanol and fuels production plants within urban areas also offers major advantages in terms of efficient energy utilization and reduced environmental impact, particularly in situations characterized by uncertain supply chains and fluctuating market prices. Biomass gasification offers an alternative carbon source to fossil fuels, and together with electrification, it may help to diversify and decentralize the energy inputs for industries traditionally dependent on natural gas, establishing resilient and sustainable energy pathways. Carbon abatement, power-to-gas and storage systems provide further advantages by mitigating the effects of seasonal availability and prices of electricity and fuel. Yet, the integration of the various energy technologies and industrial facilities calls for a systematic approach to identify optimal options for meeting the energy demands without significantly compromising the operational feasibility. Therefore, in this work, the most cost-effective technologies with minimum investment that meet the energy demands of the aluminium remelting, methanol and fuels production facilities are studied, aiming to upgrade the industrial waste heat available at low temperature to supply an urban center with variable energy needs. Implementing improved integration strategies shows the potential to reduce overall energy consumption, while achieving net-zero CO2 emissions compared to conventional scenario.

Keywords

Aluminium, Fischer-Tropsch, Methanol, Waste heat, District heating.

References

[1] Flórez-Orrego D, Dardor D, Germanier R, et al. A systemic study for enhanced waste heat recovery and renewable energy integration towards decarbonizing the aluminium industry. In: ECOS 2023 - The 36th international conference on Efficiency, Cost, Optimization, Simulation and environmental impact of energy systems. Las Palmas de Gran Canaria, https://infoscience.epfl.ch/record/303618?ln=en (2023).

[2] Andayesh M, Flórez-Orrego D, Germanier R, et al. Improved Waste Heat Management and Energy Integration in an Aluminum Annealing Continuous Furnace Using a Machine Learning Approach. Entropy 2023; 25: 1486. https://infoscience.epfl.ch/record/306214?ln=en&v=pdf

[3] Dardor D, Flórez-Orrego D, Ribeiro Domingos ME, et al. Decarbonizing the production of primary aluminium using renewable resources. In: Proceedings of the 2023 AIChE Annual Meeting, American Institute of Chemical Engineering. Orlando (FL), United States, https://infoscience.epfl.ch/record/306686?ln=en&v=pdf (2023).

[4] Flórez-Orrego D, Dardor D, Ribeiro Domingos ME, et al. Renewable energy integration and waste heat recovery for the production of sustainable jet fuel and decarbonization of industrial heating applications. In: Proceedings of the 2023 AIChE Annual Meeting, American Institute of Chemical Engineering. Orlando (FL), United States, https://infoscience.epfl.ch/record/306479 (2023).

[5] Flórez-Orrego D, Dardor D, Ribeiro Domingos ME, et al. Renewable energy integration and waste heat Valorization in Aluminum Remelting Mills for the Co-Production of Kerosene and Methanol In: ESCAPE 2024 - 34th European Symposium on Computer Aided Process Engineering. Florence, Italy, https://infoscience.epfl.ch/record/311525 (2024)

[6] Dardor D, Flórez-Orrego D, Ribeiro Domingos, M, et al. CO2 Capture and management strategies for decarbonizing secondary aluminium production. In: ESCAPE 2024 - 34th European Symposium on Computer Aided Process Engineering. Florence, Italy, https://infoscience.epfl.ch/record/311522 (2024).

[7] Flórez-Orrego D, Dardor D, Aimone L, et al. Integration of renewable energy and reversible solid oxide cells towards decarbonizing the secondary aluminium production and urban systems. In: 37th International Conference on Efficiency, Cost, Optimization, Simulation and Environmental Impact of Energy Systems. Rhodes, Greece, 2024.

[8] Dardor D, Flórez-Orrego D, Aimone L, et al. Modelling The effect of future uncertainty in energy prices on decarbonization pathways for secondary aluminium production. In: 37th International Conference on Efficiency, Cost, Optimization, Simulation and Environmental Impact of Energy Systems. Rhodes, Greece, 2024.