IPESE group is present in the Swiss Federal Office Day 2024 at the EPFL Rolex Center

Highlights

Net Zero Lab Valais consortium is composed of researchers and industrial partners from EPFL, HESSO, OIKEN and NOVELIS

Collaborators: Daniel Florez-Orrego, Dareen Dardor, Nour Boulos, Reginald Germanier, Pierre-Jean Duc, Jessen Page, François Maréchal, Manuele Margni

Past members: Lorenzo Aimone, Mohammad Andayesh, Eren Ozdemir, Cedric Dorsaz

The NetZeroLab Valais was established as part of the commitment of Novelis Sierre to reduce scope 1&2 CO2 emissions by leveraging carbon neutral solutions for aluminium manufacturing. Together with the Swiss innovation and research hub in Energypolis (HES-SO) and the local energy distributor Oiken the NetZeroLab brings together experts in areas of energy integration, modeling and simulation, life cycle analysis, furnaces operation and revamping, energy audit, and financial analysis.

A systemic study has been launched aiming at increasing the inherent efficiency of the process units and reusing waste heat of the plant’s unit operations, as well as at increasing the use of renewable energy resources available in the region 2 Different key performance indicators, such as efficiency CO2 emissions, costs, and technology readiness levels, help to evaluate the suitability of various breakthrough technological solutions

Two decarbonization projects have been rewarded with funds by the Swiss government:

- P1 Sustainable natural gas and aluminium production via biomass gasification and enhanced waste heat recovery in Novelis plant in Sierre city focused on the utilization of renewable energy resources for phasing out the fossil natural gas consumption, profiting from seasonal storage, power to gas energy technologies and processes electrification, along with rational energy use of biomass resources at higher temperatures. The goal is to use biomass to better supply high grade heat to heavy industry, which can be later cascaded for its utilization at lower temperature in a district heating network of Sierre

- P2 Enhanced waste heat recovery approach for the reduction of fuel consumption in the aluminium industry which addressed the reduction of the energy consumption and irreversibilities (triggered by large driving forces occurring inside fired furnaces) thanks to optimal temperature profiles A concept defined as Heat Transfer Interface was introduced to deal with the conjugate heat transfer phenomena between solids and gases in a simplified way It allowed elucidating the impact of the heating ramps on the furnace efficiency and residence times, informing the industry about potential gains associated to the modified scheduling of the recipes

Efforts are needed to defossilize aluminium sector which other sectors rely on food packaging, construction, automotive and aerospace industry, among others

Integrating new technologies and energy resources requires a systematic approach to identify the most cost effective solutions that satisfy the energy needs of the overall system

The selection of the most suitable heat transfer interfaces allows to reduce fuel consumption in industrial aluminium furnaces and recover waste heat for supplying needs of urban systems

Link to the report 1: https://infoscience.epfl.ch/handle/20.500.14299/240548

Link to report 2: https://infoscience.epfl.ch/handle/20.500.14299/241564

Link to poster: https://infoscience.epfl.ch/handle/20.500.14299/241570

Continuing education program: process engineering for the decarbonization of the Swiss industry

Collaborators: Daniel Florez Orrego, Dareen Dardor, Meire Ribeiro Domingos, Soline Corre, Catarina Braz, Jean M. Fuerbringer , Cyrille Platteau, Joseph Loustau, François Maréchal

Industries are typically not aware of upgrading potentials due to limited technical information on existing and new processes lack of time or skilled personnel to conduct energy audits pay walled literature, and dispersed methods and proprietary tools An inclusive and sustainable energy transition requires a prevalent formation of highly qualified engineers

Building on two decades experiences, the Industrial Process and Energy Systems Engineering group at EPFL is developing a novel modeling reporting and documentation tool, which aims to facilitate the definition, validation and sharing processes of ex ante models used in the Master of Advanced Studies in Sustainable Energy Systems Engineering The goal is to provide tools to help engineers to propose, assess and communicate the decarbonization pathways and technologies for enabling the energy transition of the Swiss industrial sectors

A database of shareable decarbonization technologies and industrial processes models, as well as the ontologies for unambiguously defining the different models interfaces, were defined. This approach facilitates reporting and reproducibility of the pinch and energy integration analyses applied to real industrial case studies.

Synthesize the principal energy integration and decarbonization concepts.

Support engineering decisions with advanced and tailor made calculation and reporting tools.

Documentation about energy audits, utility systems and a decarbonization superstructure.

The energy integration and optimization problem is handled by (R)OSMOSE tool, which selects the optimal utility systems and the operating conditions that minimize the total cost and other performance targets [2,3]

The developed technology toolbox is a documented library of the technologies used in the decarbonization superstructure of the optimization problem aimed to:

Present the background knowledge on the concepts behind the technology

List some current applications, advantages, and disadvantages of the technology

Describe model parameters and assumptions in ROSMOSE verified by literature and experts

In brief,

The MAS is proposed and designed to equip engineers with skills tools and methods needed to conceive and implement decarbonization solutions for industrial processes

Integrating other technologies and energy resources requires a systematic approach to identify the most cost effective solutions that satisfy the energy needs of the overall system

Transparent modeling tools with documented calculations, traceable versions and errors, and open source approaches must be encouraged in academia and transferred to enterprises

Link to the report: https://infoscience.epfl.ch/handle/20.500.14299/240549

Link to the poster: https://infoscience.epfl.ch/handle/20.500.14299/241572

Acknowledgements

The authors thank the Swiss Federal Office of Energy for funding the projects “Sustainable natural gas (SNG) and aluminium production via biomass gasification”, “Enhanced waste heat recovery in Novelis plant in Sierre City” within the Net Zero Lab consortium, and the project “Continuous education program process engineering for decarbonization of the Swiss industry” in the context of the preparation of the MAS.

More about NetZeroLab

https://ipese-web.epfl.ch/ipese-blog/process_design/2024-06-11-netzerolabaluminium/index.html

More about Master of Advanced Studies

References

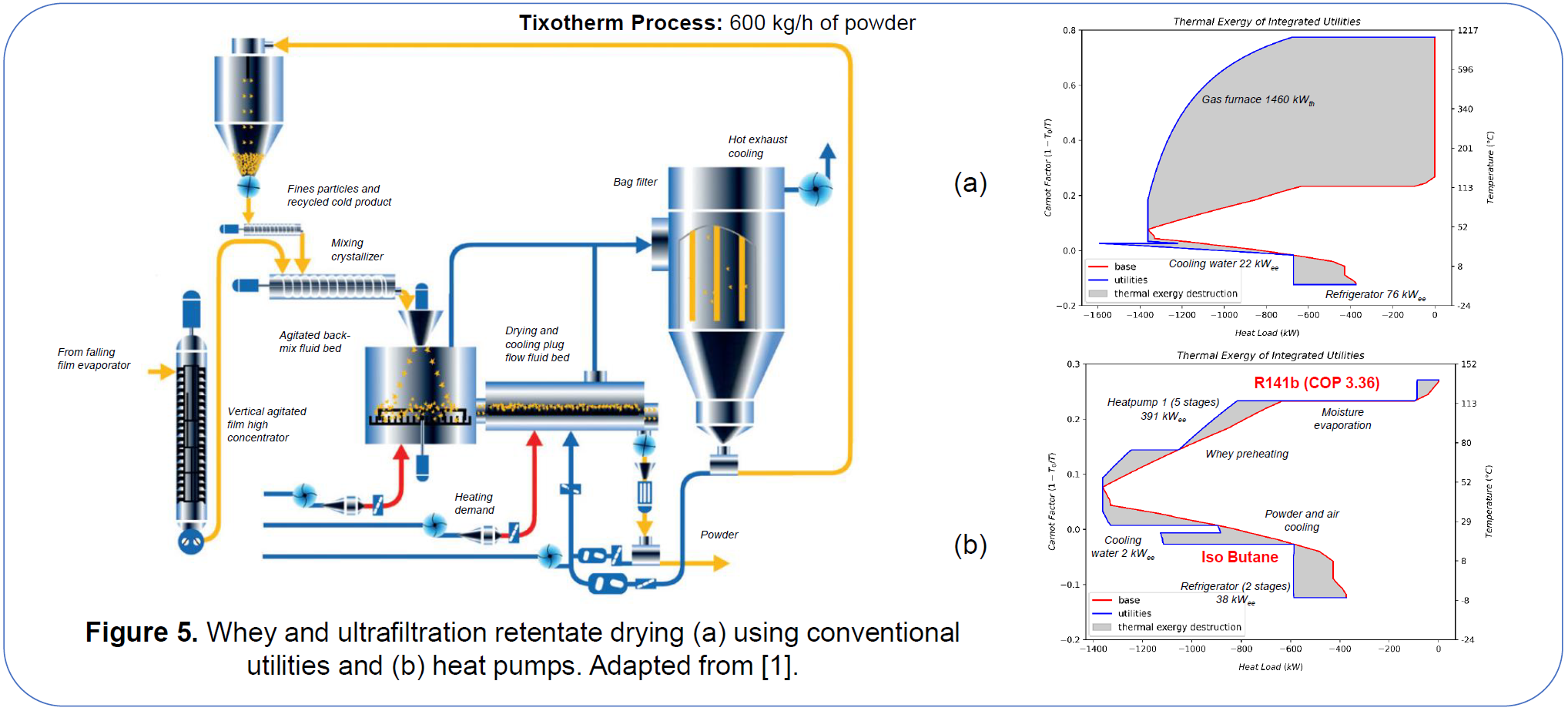

[1] Flórez Orrego D et al 2024 Sustainable natural gas and aluminium production via biomass gasification and enhanced waste heat recovery in Novelis plant in Sierre City Suisse Énergie Final Report April 2024 Swiss Federal Office of Energy

[2] Florez Orrego D et al 2024 Enhanced waste heat recovery approach for the reduction of fuel consumption in the aluminum industry IPESE group EPFL Suisse Énergie Final Report April 2024 Swiss Federal Office of Energy

[3] Florez Orrego Dardor Ribeiro Domingos, et al 2024 Continuous training program process engineering for decarbonization of the Swiss industry IPESE group EPFL Suisse Énergie, Final Report April 2024 Swiss Federal Office of Energy

[4] Flórez Orrego, D Ribeiro Domingos, M E G Maréchal, F A systematic framework for the multi time integration of industrial complexes and urban systems, 7 th International Conference on Contemporary Problems of Thermal Engineering CPOTE 2022 Warsaw, Poland, 20 th 23 th September, 2022

[5] Florez Orrego, D et al A systemic study for enhanced waste heat recovery and renewable energy integration towards decarbonizing aluminium industry 36 th Int’l Conf ECOS 2023 June 25 th 30 th, Spain

[6] Dardor D, Flórez Orrego, D Terrier, C Ribeiro Domingos, M Platteau, C Silva, J C Lopez, M, Maréchal, F ROSMOSE A web based decision support tool for the design and optimization of industrial and urban energy systems Energy, v 304 132182