Integration of renewable energy and reversible solid oxide cells towards decarbonizing the industrial and urban energy systems A novel Industrial Battery Concept for the Aluminium industry

Summary

With renewable energy penetration, the energy conversion sub-systems of an industrial process will be part of the whole energy system and will exchange energy and material flows with the main grids (electrical, gas, district heating and cooling).

Therefore, it is necessary to design the future energy conversion systems to be able not only to meet their own energy demands, but also to aid in the energy management functions of the main grids. In this way, the energy conversion sub-systems of the industrial processes will have to work in both directions: importing or exporting energy to the main grids while satisfying the process needs.

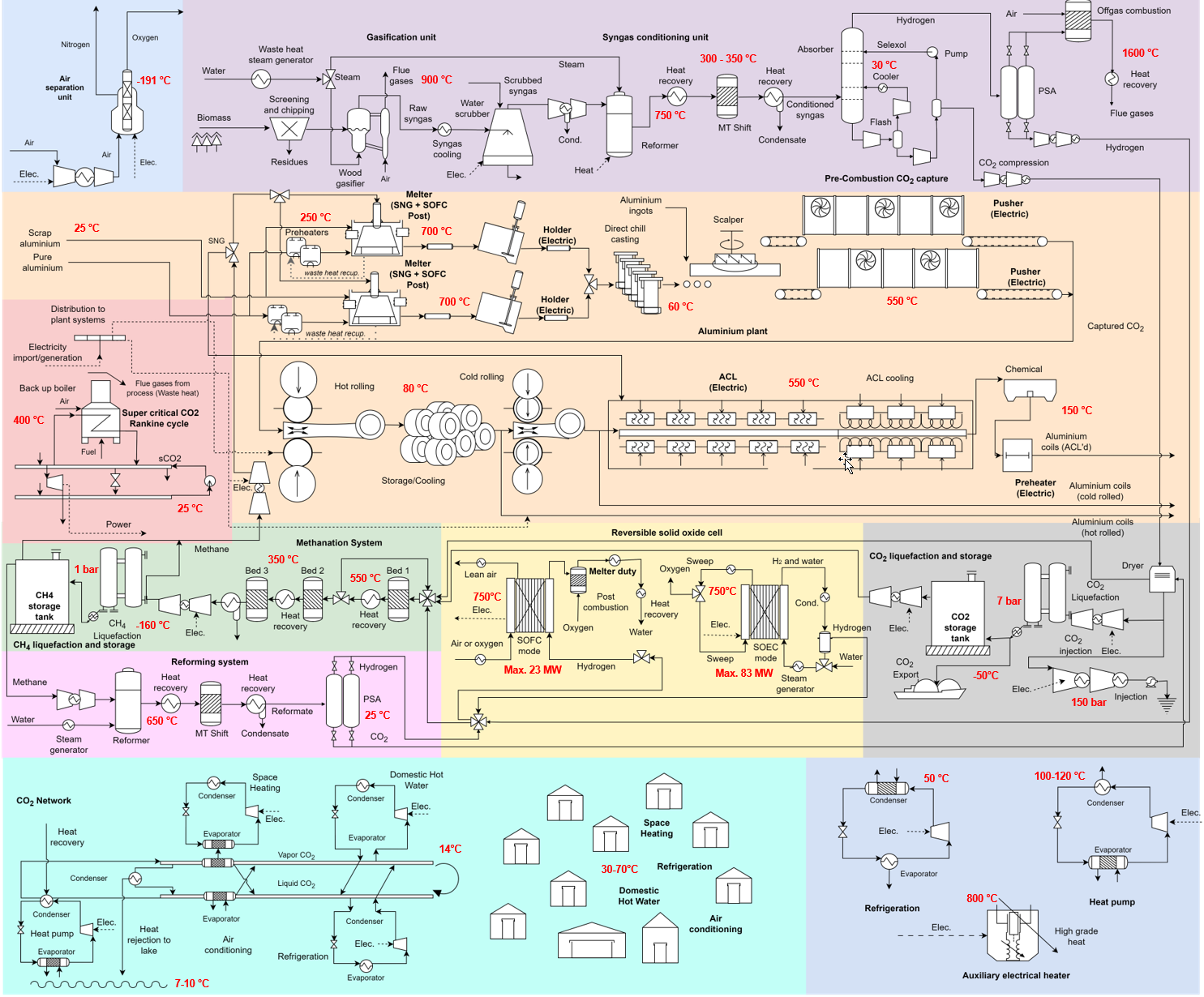

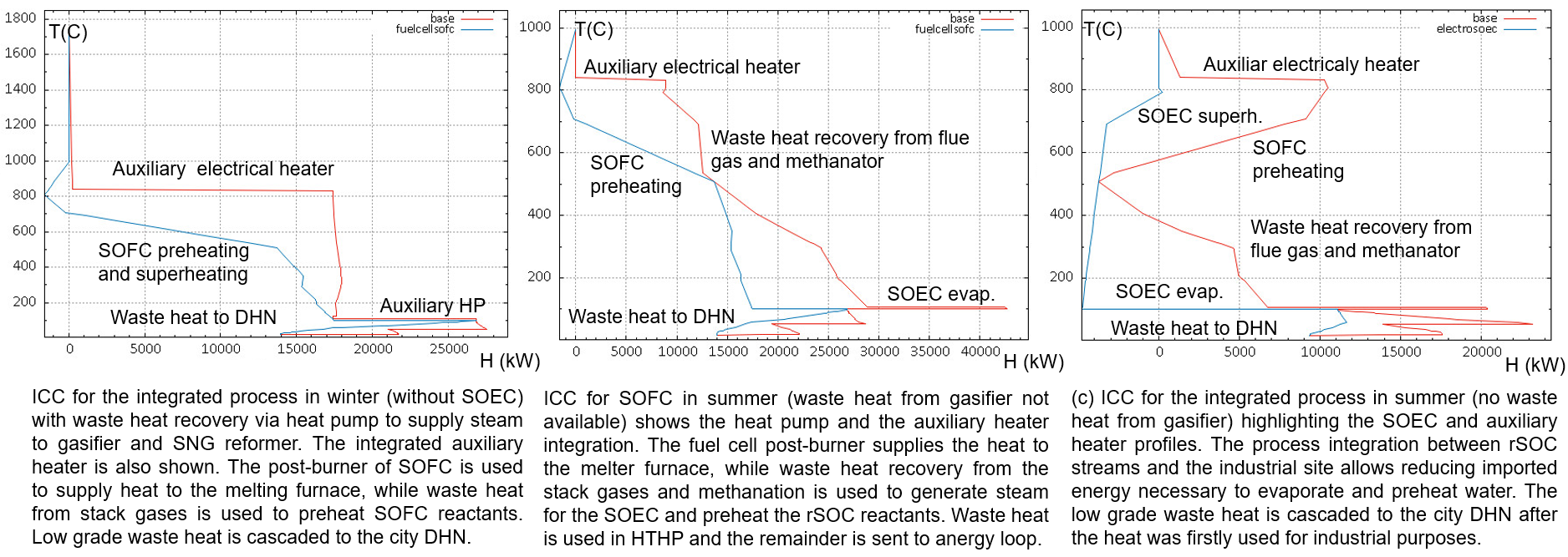

To this end, reversible SOC systems can supply electricity (in fuel cell mode) and consume electricity (in electrolysis mode). The balance of plant results in heat avialability that can be industrially used. When integrated in a process that includes fuel processing and storage system, the post-combustion of the fuel cells can become a new type of industrial burner that supplies the energy needs of the processes, while maximising the value of the exchanges with the main energy system.

In the AIChE (American Institute of Chemical Engineering) 2024 Annual Meeting held on October 27th to 31st, 2024, in San Diego, CA, USA, researchers from the Net Zero Lab Valais (NZLV) presented the outcomes of a study that evaluates the renewable energy and reversible solid oxide cells integration towards decarbonizing the industrial and urban energy systems, proposing a novel Industrial Battery Concept. The study hihglights the importance for capitalizing on the high temperature waste heat available for driving fuel and CO2 management strategies, whereas supplying the energy and power needed by the casthouse and rolling plants of the industrial partner Novelis. The integration of the CO2-based district heating network in the city of Sierre has been also considered.

Key words: Reversible Solid Oxide (rSOC) cells, Seasonal storage, Net Zero, Aluminium production, Decarbonization, Carbon capture, Urban systems, CO2 Networks

Introduction

Aluminium sector relies on natural gas for recycling scrap into feedstock, contributing ~2% to the global industrial CO2 emissions [1].

Hydric resources are used as cooling media for aluminium direct chill casting, and waste heat is typically rejected to nearby water bodies, instead of using it in district heating networks.

Process integration between aluminium plants, urban and regional energy systems promotes energy security, lower environmental impact and energy-efficient use of valuable resources.

Renewable energy integration, like electrification and biomass gasification, helps diversify and defossilize heavy industry energy supply, traditionally based on fossil natural gas.

Power-to-gas-to-power, carbon capture and use, and storage systems offer further advantages by mitigating the effects of seasonal availability and prices of electricity and fuels [2].

By implementing an industrial battery capable of handling renewable energy intermittency [3], reversible solid oxide cells can partially supply heat to fired furnaces, as well as electricity to electrical furnaces, rolling processes and heat pumping systems of the district heating network.

Methods

Base case scenario consists of standalone operation of aluminium plant using natural gas, as well as urban heating systems based on direct biomass combustion.

Integrating novel technologies and industrial facilities requires a systematic approach to identify the most cost-effective solutions that satisfy the energy needs of the overall system.

A process integration and optimization problem is handled by OSMOSE platform, which applies a MILP algorithm to find the seasonal load and dispatch of the technologies to minimize the total operating cost, subject to constraints of heat cascade, power balance and solution feasibility [4]:

Industrial waste heat available at low temperature is upgraded to supply the seasonal energy needs of an urban system via anergy CO2 network and heat pumps, instead of burning biomass for heating purposes at low temperatures.

Results

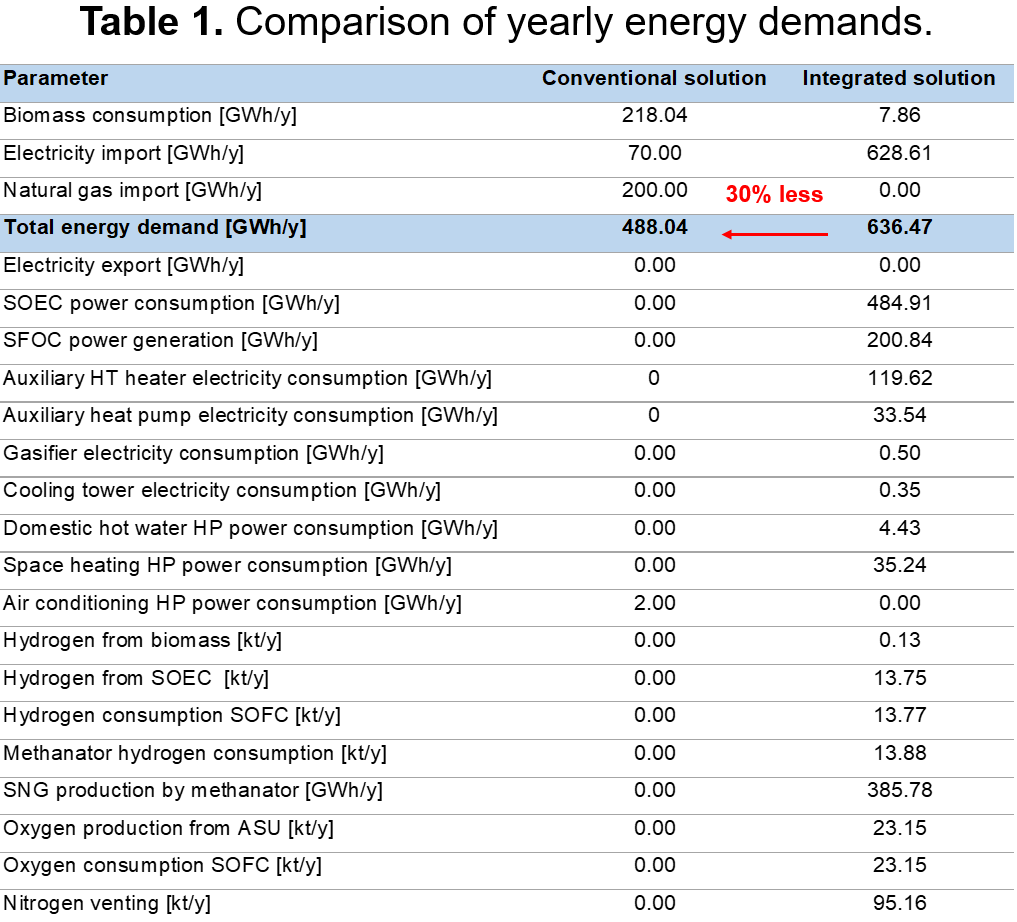

In the integrated case, SOFC power generation reaches 200 GWh/y, or around 30% of the total electricity import. The post-combustor of SOFC supplies heat to the melter furnace (800-1000 kWh/t) with facilitated CO2 capture thanks to an oxyfuel setup.

The hydrogen production by the SOEC units is 13.75 kt/y. The methanator yields 385 GWh/y of SNG. The hydrogen production from gasification units is 0.13 kt/y.

The oxygen production by SOEC is balanced in winter by an auxiliary ASU (23.15 kt/y).

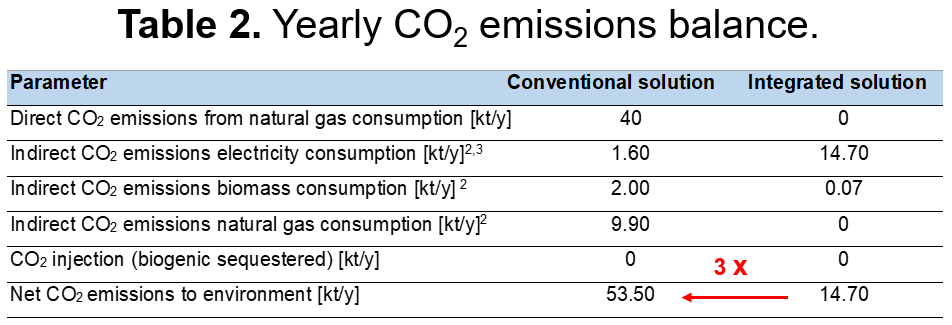

In the integrated case, all CO2 captured is stored or used to produce SNG during summer (i.e. no CO2 injection or mineralization). In the conventional scenario, fossil and biogenic emissions are eventually released to environment.

The total (direct + indirect) fossil CO2 emissions of the integrated system amount 14.77 kt/y. The indirect fossil CO2 emissions arising from biomass and electricity supply chains are 0.07 and 14.70 kt/y, respectively.

The standalone operation of aluminium production plant brings about three times more CO2 emissions, compared with the integrated solution.

In the integrated scenario, total energy demand is around 30% higher, and total incremental cost is about 35% higher due to the additional investment (~22 MEur/y).

Carbon tax associated to fossil direct and indirect CO2 emissions in the conventional scenario adds a penalty of ~3.5 MEur/y.

About 100 GWh/y of waste heat can be cascaded to the city after its use at higher temperatures in industrial applications. An additional 10% is harvested from ambient sources to balance the urban demands.

Heat pumps will play an important role in industrial decarbonization pathways [5].

Conclusions

More efforts are needed to defossilize aluminium sector on which other sectors rely, such as cargo, food packaging, and automotive industry. Improved integration strategies can reduce carbon footprint, whereas maintaining attractive energy efficiencies and reasonable incremental investment. Up to three times less fossil CO2 emissions can be attained if electrification, CO2 upgrading and rSOC plus storage systems, together with biomass gasification, are adopted. Combined heat and power can be partly supplied to the industrial plant and urban systems by using an industrial battery of renewable electricity leveraging rSOC and storage technology. Carbon taxes favor the deployment of power-to-gas and storage systems, and promote better CO2 and renewable energy management approaches, phasing out fossil fuels dependency.

List of other publications by NetZeroLab

[1] Flórez-Orrego D, Dardor D, Germanier R, et al. A systemic study for enhanced waste heat recovery and renewable energy integration towards decarbonizing the aluminium industry. In: ECOS 2023 - The 36th international conference on Efficiency, Cost, Optimization, Simulation and environmental impact of energy systems. Las Palmas de Gran Canaria, https://infoscience.epfl.ch/record/303618?ln=en (2023).

[2] Andayesh M, Flórez-Orrego D, Germanier R, et al. Improved Waste Heat Management and Energy Integration in an Aluminum Annealing Continuous Furnace Using a Machine Learning Approach. Entropy 2023; 25: 1486. https://infoscience.epfl.ch/record/306214?ln=en&v=pdf

[3] Dardor D, Flórez-Orrego D, Ribeiro Domingos ME, et al. Decarbonizing the production of primary aluminium using renewable resources. In: Proceedings of the 2023 AIChE Annual Meeting, American Institute of Chemical Engineering. Orlando (FL), United States, https://infoscience.epfl.ch/record/306686?ln=en&v=pdf (2023).

[4] Flórez-Orrego D, Dardor D, Ribeiro Domingos ME, et al. Renewable energy integration and waste heat recovery for the production of sustainable jet fuel and decarbonization of industrial heating applications. In: Proceedings of the 2023 AIChE Annual Meeting, American Institute of Chemical Engineering. Orlando (FL), United States, https://infoscience.epfl.ch/record/306479 (2023).

[5] Flórez-Orrego D, Dardor D, Ribeiro Domingos ME, et al. Renewable energy integration and waste heat Valorization in Aluminum Remelting Mills for the Co-Production of Kerosene and Methanol In: ESCAPE 2024 - 34th European Symposium on Computer Aided Process Engineering. Florence, Italy, https://infoscience.epfl.ch/record/311525 (2024)

[6] Dardor D, Flórez-Orrego D, Ribeiro Domingos, M, et al. CO2 Capture and management strategies for decarbonizing secondary aluminium production. In: ESCAPE 2024 - 34th European Symposium on Computer Aided Process Engineering. Florence, Italy, https://infoscience.epfl.ch/record/311522 (2024).

[7] Flórez-Orrego D, Dardor D, Aimone L, et al. Integration of renewable energy and reversible solid oxide cells towards decarbonizing the secondary aluminium production and urban systems. In: 37th International Conference on Efficiency, Cost, Optimization, Simulation and Environmental Impact of Energy Systems. Rhodes, Greece, 2024.

[8] Dardor D, Flórez-Orrego D, Aimone L, et al. Modelling The effect of future uncertainty in energy prices on decarbonization pathways for secondary aluminium production. In: 37th International Conference on Efficiency, Cost, Optimization, Simulation and Environmental Impact of Energy Systems. Rhodes, Greece, 2024.

[9] Flórez-Orrego D, Dardor D, Ribeiro Domingos, M, et al., Integration of renewable energy and reversible solid oxide cells towards decarbonizing the secondary aluminium production and urban systems. 2024 AIChE Annual Meeting - American Institute of Chemical Engineering. October 27th – 31st, 2024, San Diego, CA, USA.

[10] Ribeiro Domingos, M, Flórez-Orrego D, et al., Systematic analysis on the energy transition pathways for sustainable natural gas production. 2024 AIChE Annual Meeting - American Institute of Chemical Engineering. October 27th – 31st, 2024, San Diego, CA, USA.