Webinar on the results of the IEA Annex 58 - Switzerland - Design of a web-based decision support tool for the industrial high temperature heat pumps integration

Summary

In this webinar, the contributions of the Swiss team to the IEA Annex 58 on the integration of high temperature heat pumps in industrial process have been presented. EPFL partnered with CSD engineers, HEIG-VD and OST in Switzerland to identify heat pump integration potentials in CREMO, ELSA and SPIESS companies in Switzerland.

A short description of the factors that led to the definition of the product profile is introduced, followed by the tool workflow for process integration and pinch analysis. The principle of operation of the OSMOSE backend algorithm is presented. The data input interfaces such as Excel-based and FlexiCode strategies are explained and exemplified. The HP superstructure and ETs database available with the tool are described. A simplified GUI developed for the least skilled end-users is also demonstrated. Finally, the typical results, reporting and validation steps, considering examples of use are presented. The webinar of the web-based decision support tool finalizes with the conclusions and path forward.

Key words: Heat pumps, Energy integration, Net Zero, Web-based tool, Decarbonization, Superstructure, Refrigerants

Objectives

To introduce a web-based decision support tool for the design and integration of industrial high-temperature heat pumps.

To design a flexible, open-source tool for modeling, analyzing, and documenting the energy integration results of industrial processes.

To inform end-users about the importance and benefits of the application of process integration techniques to the industrial processes.

Relevance and challenges

Increasing number of technological options and operating conditions.

A comparative analysis requires a suitable modeling, optimization, visualization and reporting tool.

Lack of intuitive, open-source tools to develop fast and accurate Pinch Analyses.

Methods

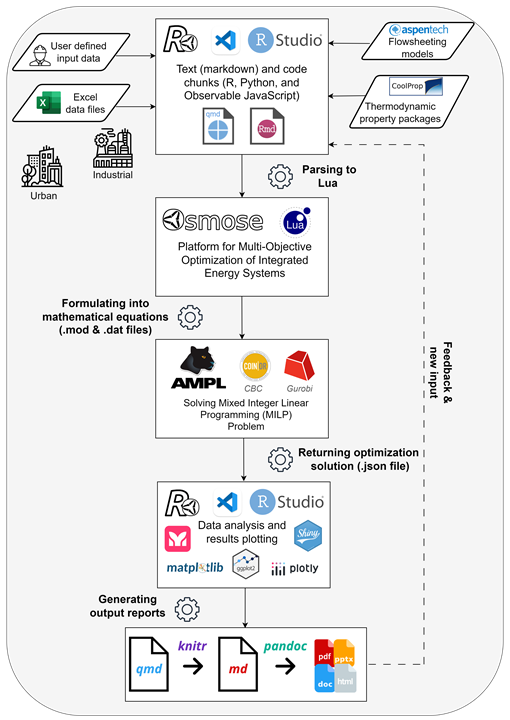

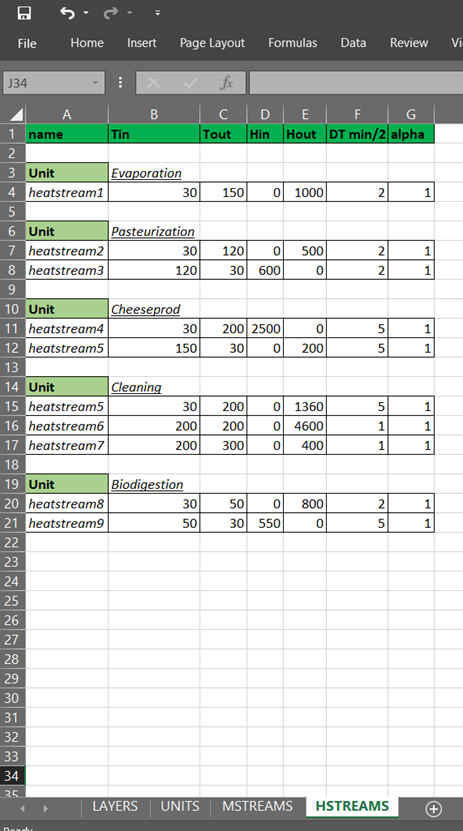

Process data from audits is input via Excel template, flowsheeting software or by directly coding (Python).

Data input via: (i) manual insertion of hot and cold streams in FlexiCode, (ii) imported from either Excel, (iii) flowsheeting software.

Data can be collected on-site in an acquisition OPC (Open Platform Communications) servers, either in .json or .csv format (or compatible formats).

Vendors’ data, incl. Ts, T lift, COP and capacity to assess commercial solutions.

Open-source libraries (e.g. Coolprop) calculate thermodynamic properties.

Frontend for data input and OSMOSE engine execution, solves synthesis and optimization problem.

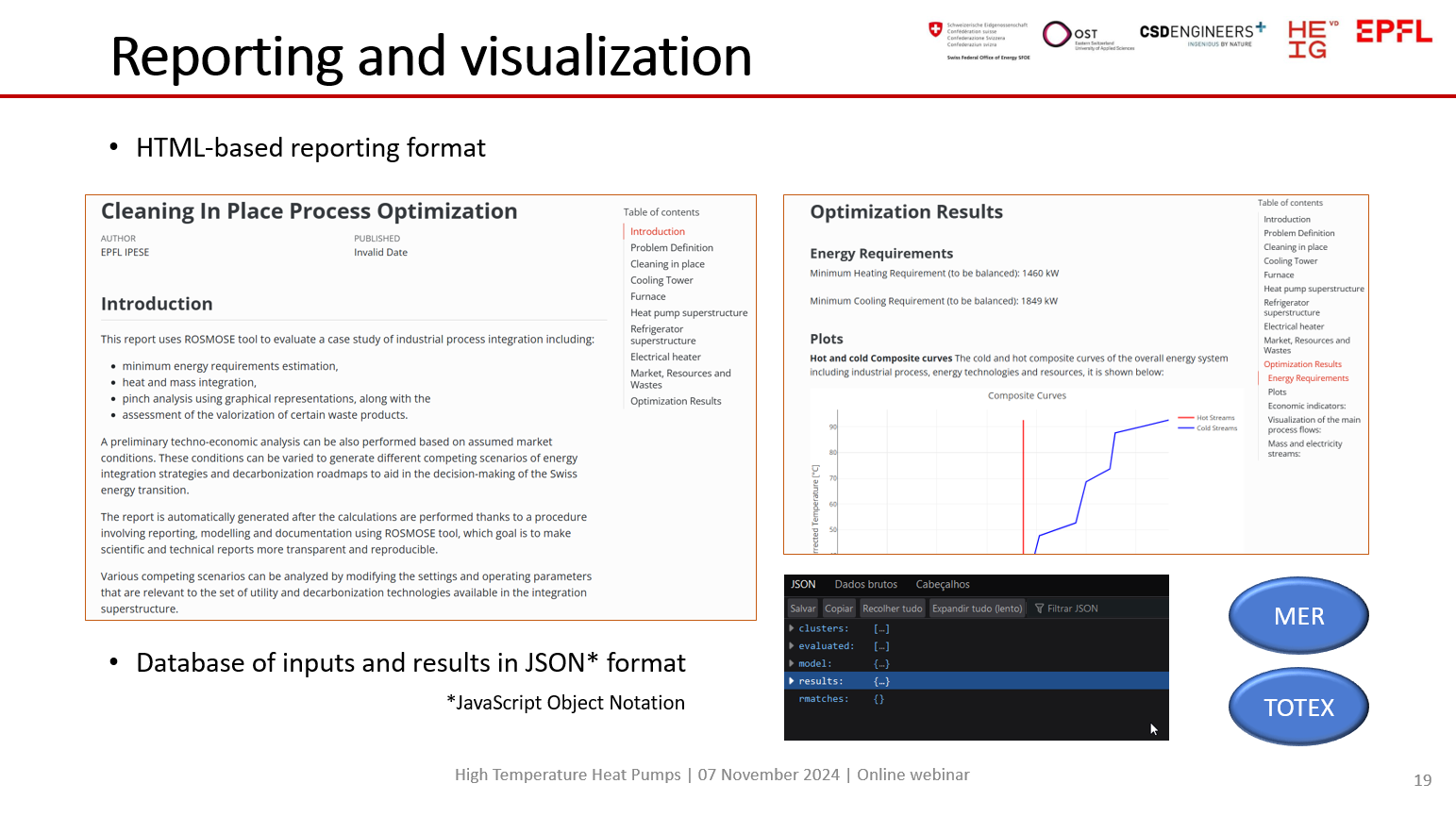

.json output file with information needed to visualize and calculate KPIs.

User-friendly .html report summarizes problem definition, assumptions, and PI/PA results (tables, plots, etc.) in a structured and shareable format.

Pinch point(s) and penalized heat exchanges are spotlighted. Actions towards better integrating the energy systems can be investigated.

Feedback loop to improve features of utility systems. HP superstructure can be refined.

(R)OSMOSE Rmarkdown-based OSMOSE - Multi-Objective Optimization of Integrated Energy Systems Process integration tool developed at IPESE group in EPFL.

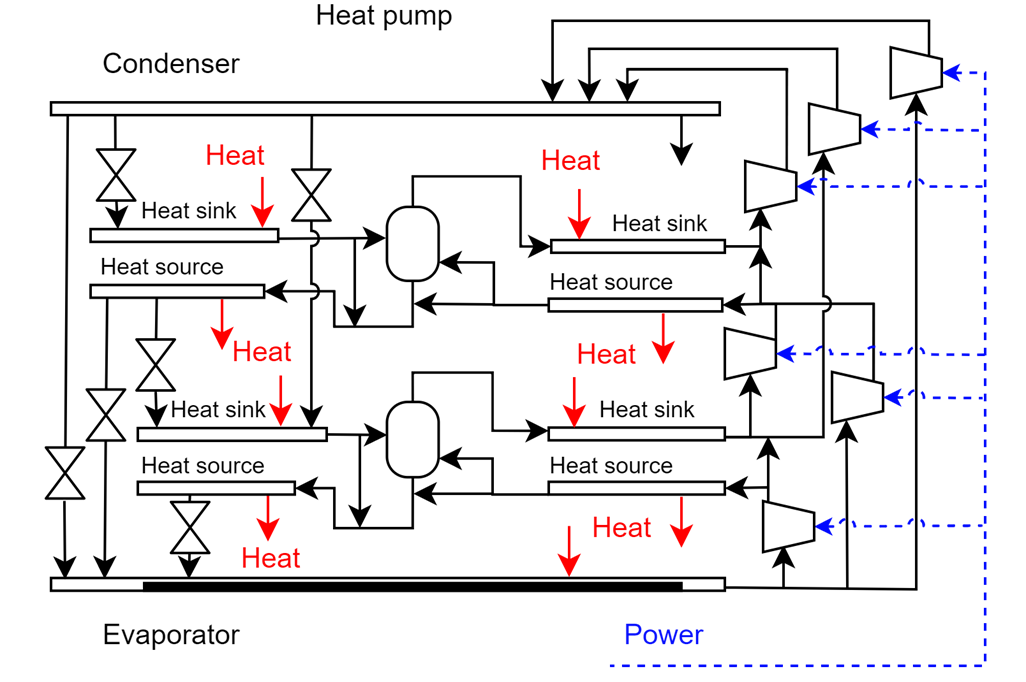

The web-based decision tool relies on Pinch Analysis and uses a superstructure-based mixed integer linear programming (MILP) optimization algorithm.

(R)OSMOSE selects the optimal energy technologies and utility systems to supply the energy demands with a minimum overall production cost, including capital and operational expenditures.

Superstructure of competing utilities (e.g. furnace, electrical heater, engines, water cooling, refrigeration, heat pumps, photovoltaic systems and decarbonization technologies, such as biomass, CCS, etc.).

Integrates various software and tools: (i) database handling routines (.csv and .json), (ii) thermodynamic libraries (Aspen, Coolprop), (iii) optimization suites (AMPL), and (iv) data visualization (GNU Plot, Plotly).

The heat pump superstructure considers a combination of evaporators, condensers, mixers, economizers, saturators, superheaters, subcoolers, and throttling valves, as well as optimal working fluids and operating conditions (e.g. temperatures, # stages, discharge T, compressor type, etc.)

The list of potential fluids includes: ‘IsoButane’, ‘Methane’, ‘Ethylene’, ‘water’, ‘Ammonia’, ‘n-Propane’, ‘R1234yf’, ‘Propylene’, ‘R32’, ‘Ethane’, ‘CarbonDioxide’, ‘R245fa’, ‘R1233zd(E)’, ‘R1234ze(Z)’, ‘R1234ze(E)’, ‘R365MFC’, ‘n-Pentane’, ‘Isopentane’, ‘n-Butane’, ‘R134a’,‘R152a’

Results

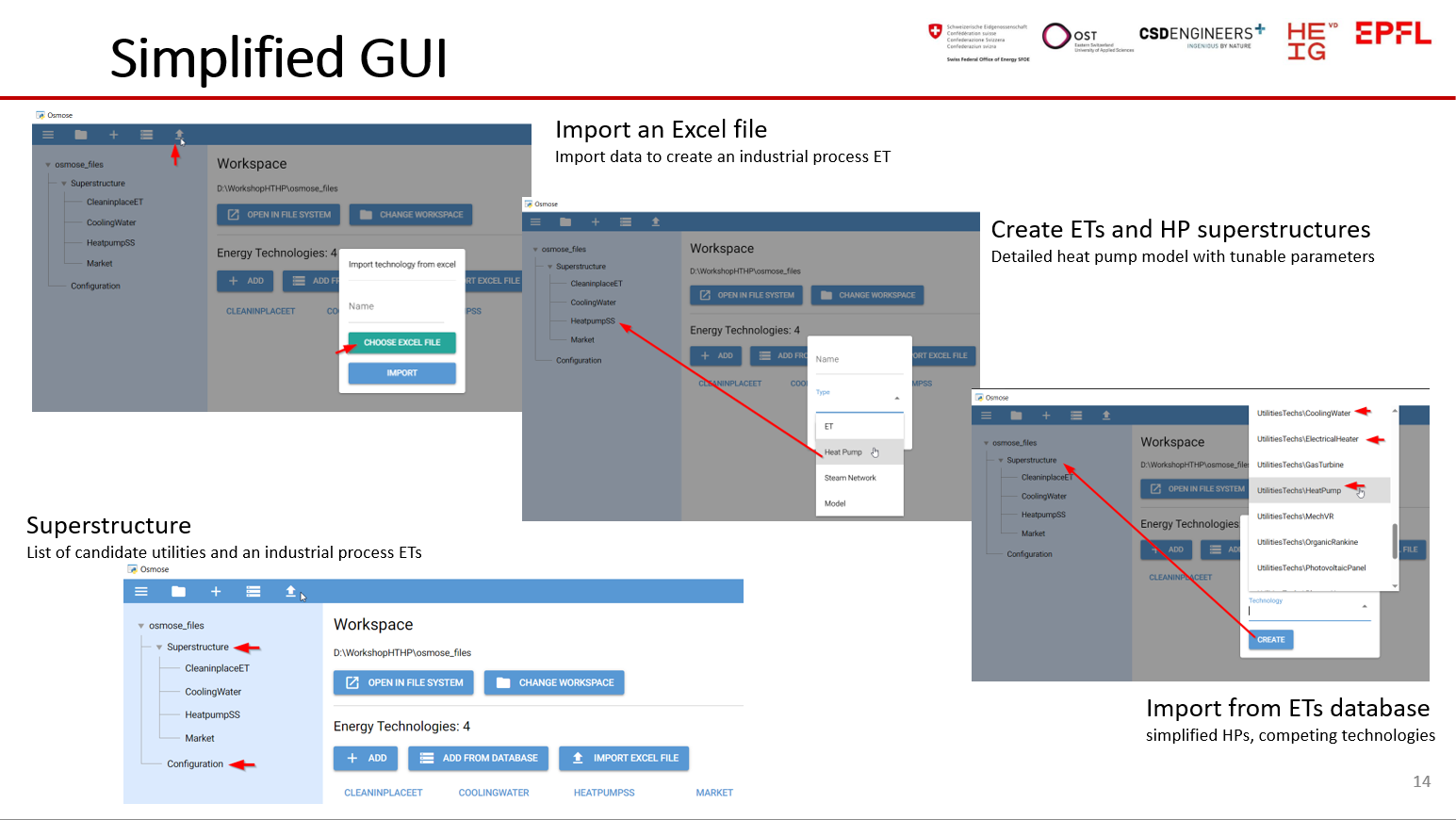

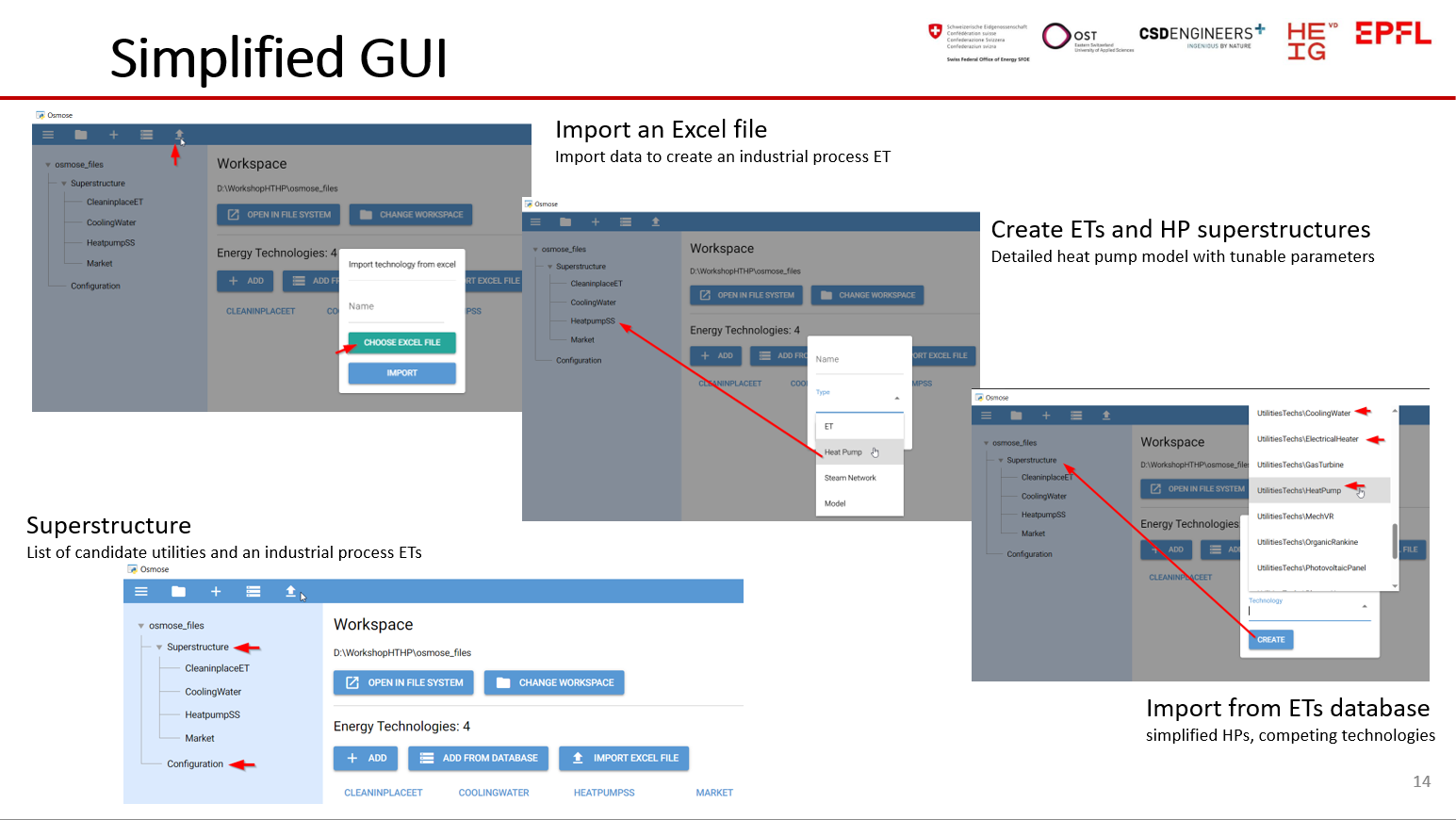

The development of the web-based supporting tool required the adaptation to different end-used profiles, including technicians, engineers, managers, pinch experts and reseachers. According to a survey performed on the Wärmepumpentagung on 26th June 2024, a part of the end-user requested a Simplified GUI to facilitate the opt-in of those with minimum programming skills.

In this way, ROSMOSE execution can be achieved with the minimum interaction with the Visual Studio Code IDE for accessing the Quarto suite.

The tool processes the input data for calculating:

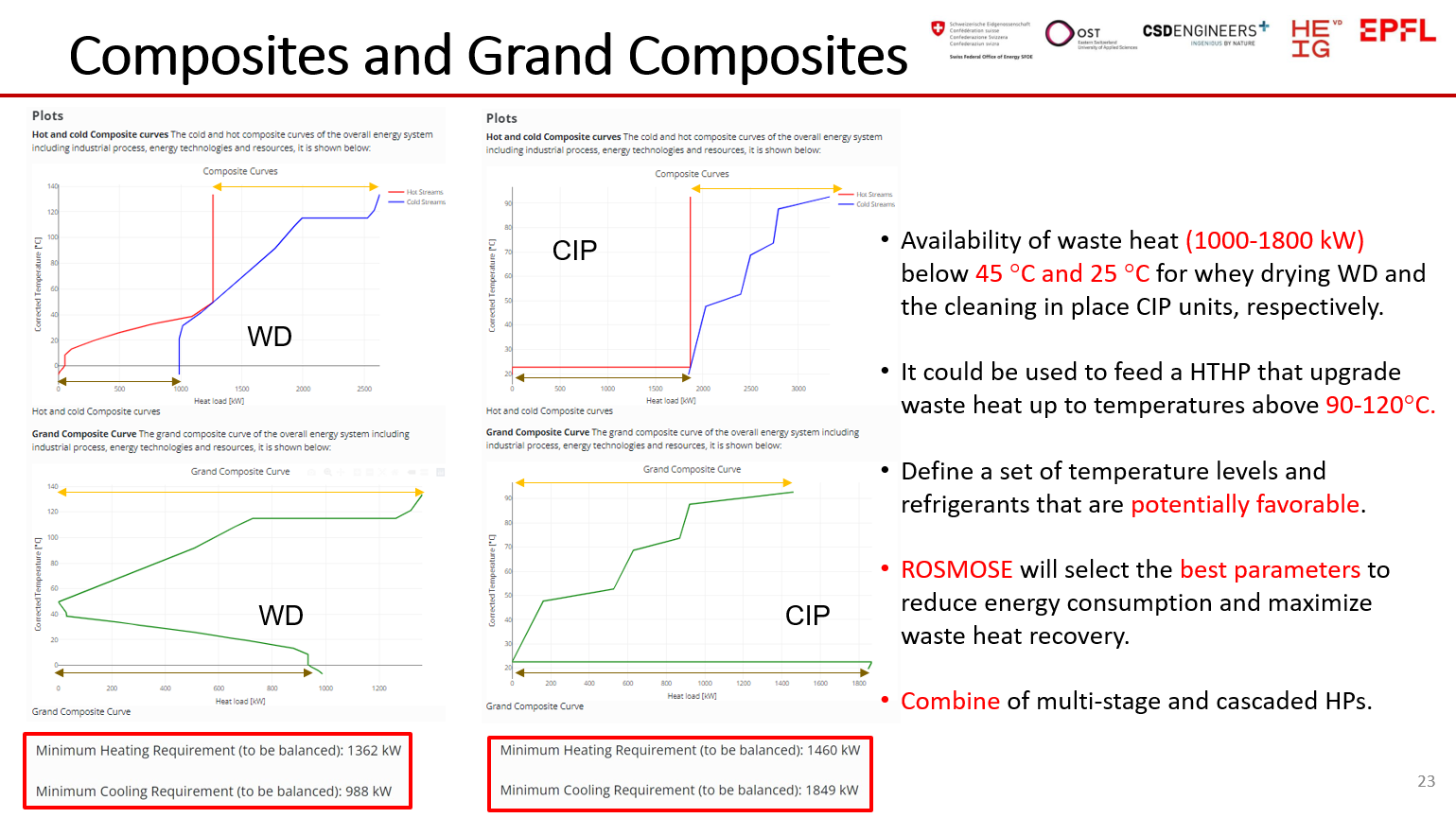

Minimum energy requirements (MER) (heating and cooling),

Pinch point temperature(s),

Graphical representations of the hot and cold composite curves (CC),

Graphical representations of the grand composite curve (GCC),

Graphical representations of the Carnot composite curve (CCC),

Levels of temperature for suitable condensers and evaporators & fluids selection for HP systems,

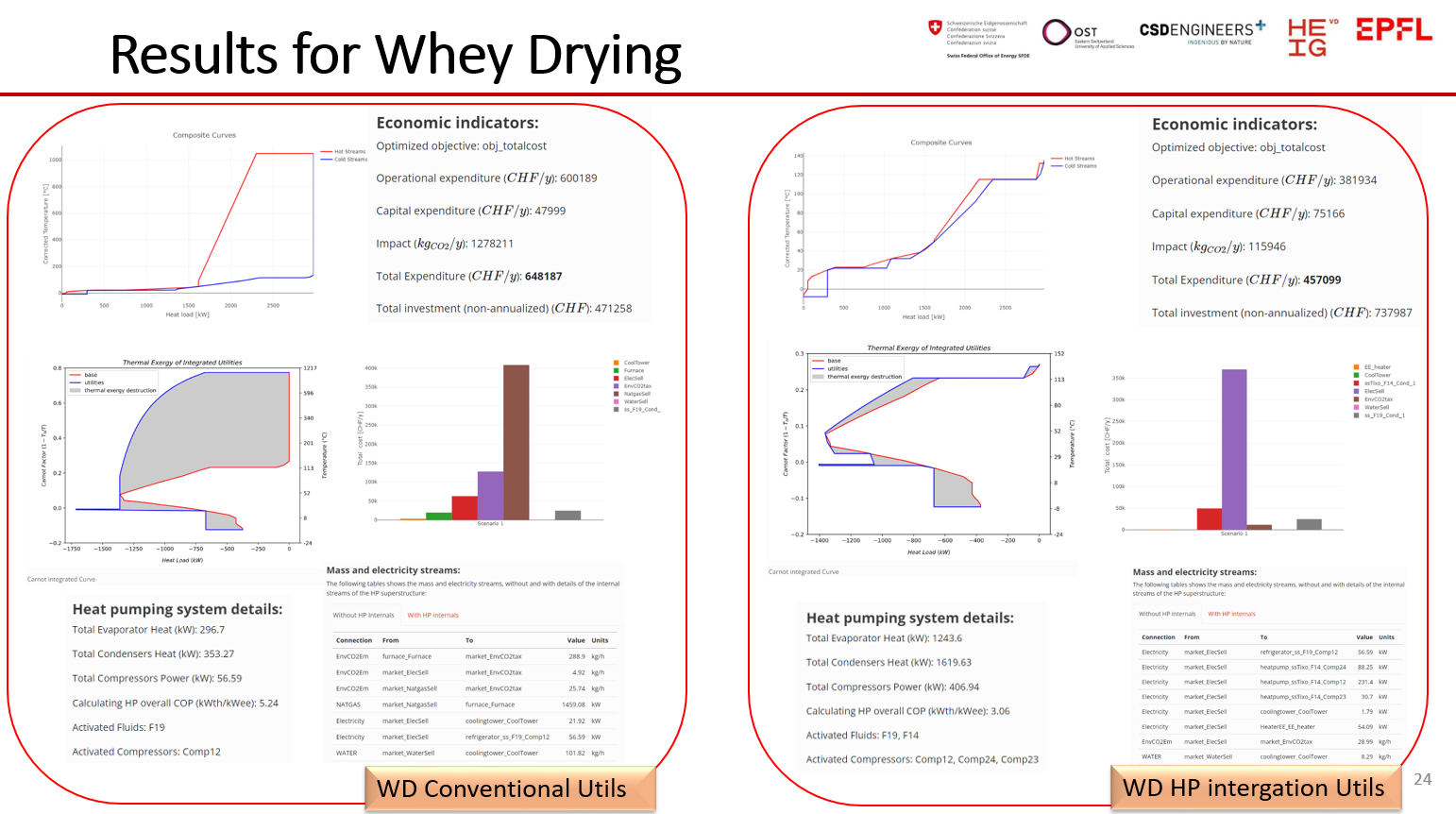

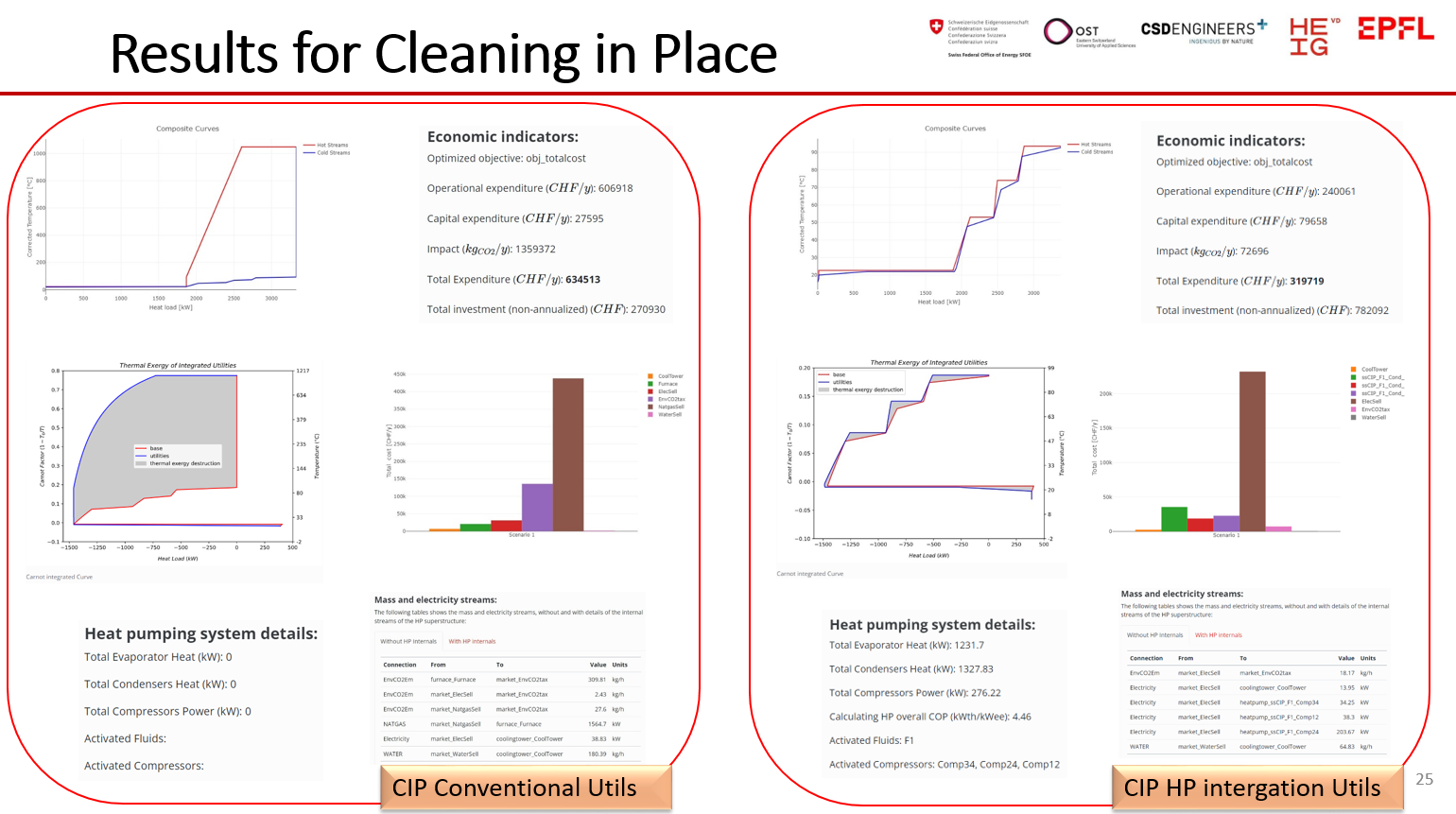

Compression power and coefficient of performance (COP) of HP systems,

Mass and energy flows of the analyzed process (energy imports and exports, CO2 emissions),

Estimated total costing (capex + opex)

Tailored KPIs (using FlexiCode approach)

Industrial case studies

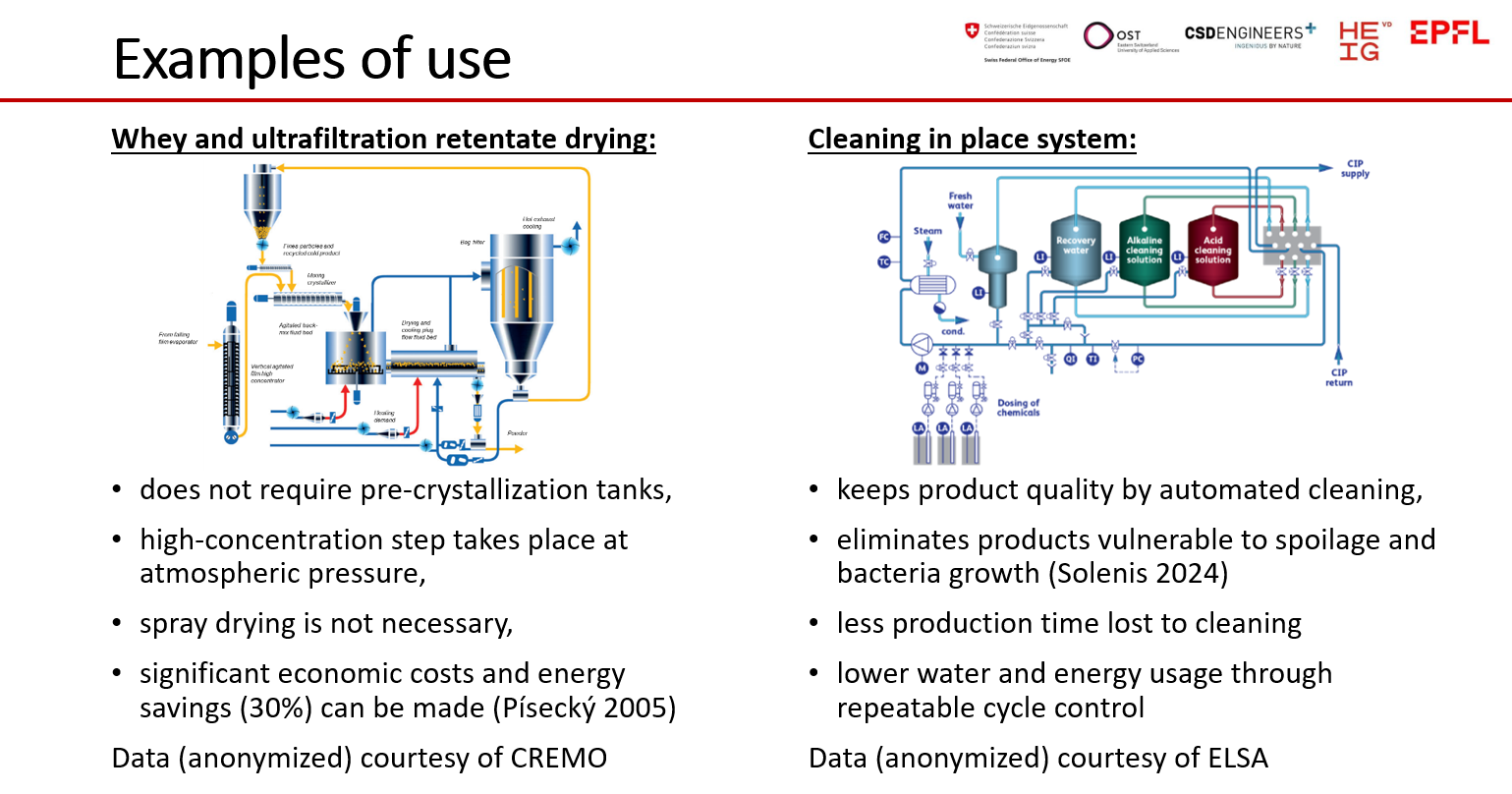

Two industrial processes are presented as examples of utilization of the web-based decision support tool:

Link to access the presentation slides

From EPFL InfoScience, from Sweet DecarbCH website

Link to access to the videos of this and other webinar presentations

Conclusions

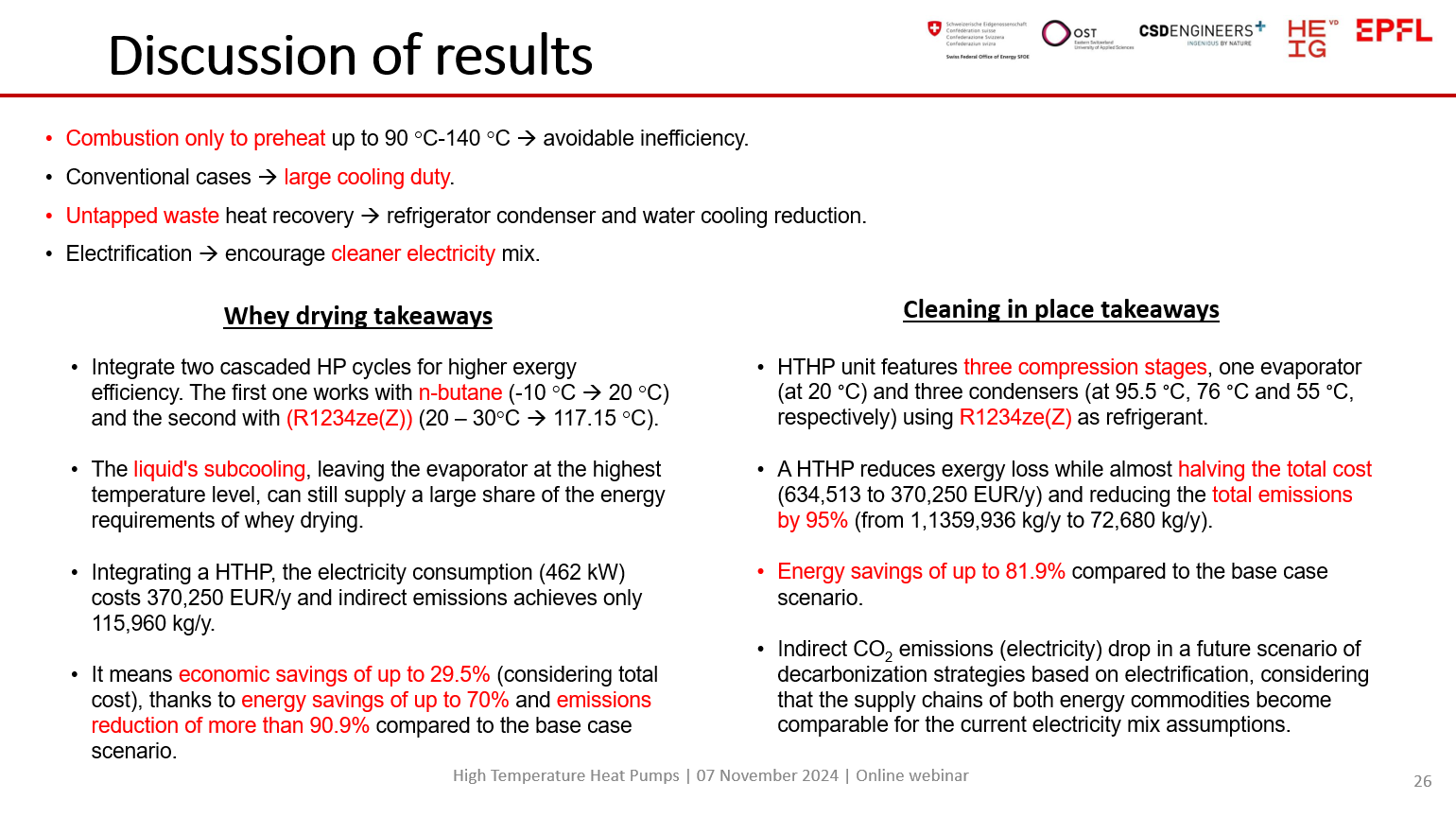

Process electrification and waste heat valorization are crucial to defossilize heat supply in food and beverage industries (favorable temperature levels).

Competition between different utility systems a tool to systematically compare the performance of those alternative technologies.

Automated computational and reporting tools modeling, reporting and comparing energy integration scenarios.

CO2 tax and waste heat valorization HP deployment by offsetting initial investments.

Challenges related to reliability, space budget and maintainability risk perception within firms.

Preliminary analyses significant waste heat recovery using HTHPs and environmentally friendly.

Path forward

Massive deployment of the web-based tool, training programmes, and business model.

Servers hosting and confidentiality, local installation vs. external servers.

Installation, maintenance, and handling of confidential data in servers hosted by EPFL.

Adopt a scalable infrastructure and address robust and secure data handling (authentication).

Containerization (e.g., Docker) of required libraries for optimization and visualization avoiding external servers.

Lessons and takeways

Assessing the competition between different utility systems requires a tool to systematically and objectively compare the performance of alternative technologies.

Automated computational and reporting tools can speed up modeling, reporting and comparison of energy integration scenarios.

Adopting new decision-support tools can be facilitated by integrating familiar data-handling platforms, like Excel, while still benefiting from the flexibility of open-source programming languages and libraries.

Developing decision support tools that fit different users’ profiles entails prioritizing intuitive, flexible and versatile open-source toolkits.

An inclusive and sustainable energy transition will require equipping qualified engineers with powerful tools to leverage models databases and routines for industrial diagnosis and optimization.

Key challenges in ensuring the sustainability and consistency of open-source tools include addressing web scalability, maintainability, server hosting, and confidentiality issues.

Projects and courses that have been and will use and further validate the tool

HTHP Annex 58 Swiss (IEA)

Task XXIV IETS TCP (IEA)

Master of Advanced Studies (EPFL/HESSO)

Pinch Bot (SFOE)

Advanced Energetics (Graduate course at EFPL)

Industrial projects in IPESE (EPFL, Novelis, LDC, Buhler, Richemont, Terega, Morand, Hermes, CIMO, ELSA, CREMO, SPIESS, etc.)

Acknowledgments

The team acknowledges the Swiss Federal Office of Energy (SFOE) for supporting the project: Annex 58 HTHP-CH: Integration of High-Temperature Heat Pumps in Swiss Industrial Processes N°.SI/502336-01

Contributors

Daniel Florez-Orrego, PhD Mech. Eng (Colombia)

Cyrille Platteau, IT specialist (France)

François Maréchal, PhD Chem. Eng (Switzerland)

Meire Ribeiro Domingos, PhD Chem. Eng. (Brazil)

Dareen Dardor, PhD Student, Chem. Eng. (Lybia)

Soline Corre, PhD Student, Mech. Eng. (Switzerland)

Lander Cortvriendt, MSc. Chem. Eng. (Belgium)

Joao Ferreira da Silva, IT specialist (Portugal)

Joseph Loustau, IT support (Switzerland)

List of related publications

[1] Florez-Orrego, D., et al. A systematic framework for the multi-time integration of industrial complexes and urban systems. 7th Intl Conf. CPOTE, 20th-23th September, 2022. Warsaw, Poland.

[2] Florez-Orrego, D. et al. Heat pumping and renewable energy integration for decarbonizing brewery industry and district heating. In: Computer Aided Chemical Engineering. Elsevier, pp. 3177–3182. 2023

[3] Flórez-Orrego, D., et al. Techno-economic and environmental analysis of high temperature heat pumps integration into industrial processes: the ammonia plant and pulp mill cases. Sust. Energy Technol. Assess 2023; 60: 103560.

[4] Dardor, D., Florez-Orrego, D. et al. ROSMOSE: A web-based optimization tool to aid decision-making for the design and operation of industrial and urban energy systems, Energy, v. 304, 2024, pp132182.

[5] Florez-Orrego, D., Dardor, D., Ribeiro Domingos MEG, et al (2024) Continuous training program: process engineering for decarbonization of the Swiss industry. SuisseEnergie, Swiss Federal Office of Energy, https://infoscience.epfl.ch/handle/20.500.14299/240549

[6] Florez-Orrego, D., Dardor D., Ribeiro Domingos, M., et al (2024) A web-based decision support tool for the design and integration of industrial high-temperature heat pumps. Wärmepumpen Tagung, Bern, June 26th, 2024.